4th May 2022

Cambridge Electric Cement

Three Cambridge engineers, Dr Cyrille Dunant, Dr Pippa Horton and Professor Julian Allwood, have filed a patent and been awarded new research funding for their invention of the world’s first ever zero-emissions cement.

Replacing today’s cement is one of the hardest challenges on the journey to a safe climate with zero emissions. There are many options to make cement with reduced emissions, mainly based on mixing new reactive cement (clinker) with other supplementary materials. However, until now, it has not been possible to make the reactive component of cement without emissions. The new invention achieves this for the first time.

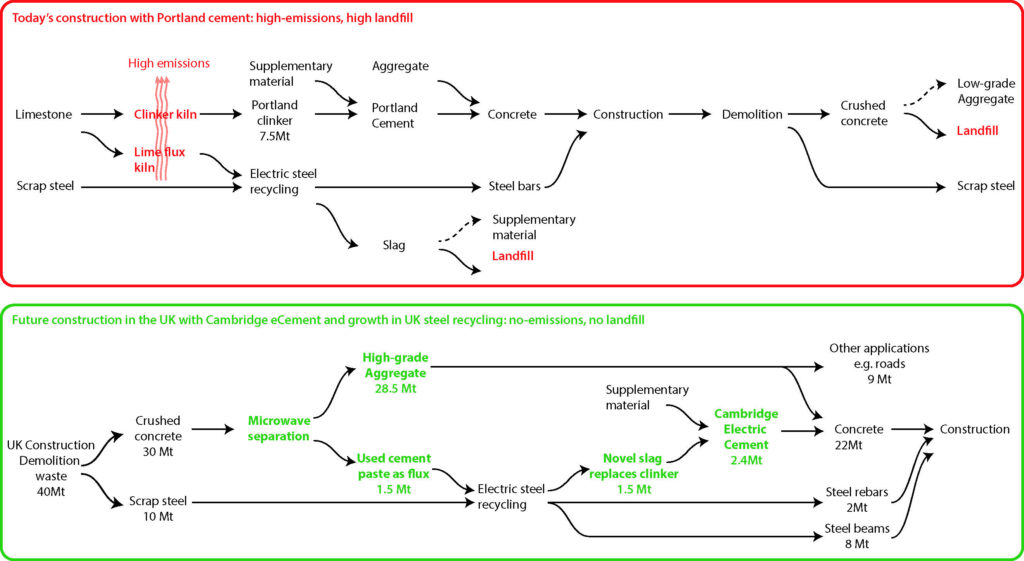

The inspiration for Cambridge Electric Cement struck inventor Cyrille Dunant, when he noticed that the chemistry of used cement is virtually identical to that of the lime-flux used in conventional steel recycling processes. The new cement is therefore made in a virtuous recycling loop, that not only eliminates the emissions of cement production, but also saves raw materials, and even reduces the emissions required in making lime-flux. The new process begins with concrete waste from demolition of old buildings. This is crushed, to separate the stones and sand that form concrete from the mixture of cement powder and water that bind them together. The old cement powder is then used instead of lime-flux in steel recycling. As the steel melts, the flux forms a slag that floats on the liquid steel, to protect it from oxygen in the air. After the recycled steel is tapped off, the liquid slag is cooled rapidly in air, and ground up into a powder which is virtually identical to the clinker which is the basis of new Portland cement. In pilot-scale trials of the new process, the Cambridge team have demonstrated this combined recycling process, and the results show all the properties of cement made by today’s conventional process.

The new cement was invented as part of the large multi-university UK FIRES programme led by Professor Allwood, which aims to enable a rapid transition to zero emissions based on using today’s technologies differently, rather than waiting for the new energy technologies of hydrogen and carbon storage. Invention of the cement has been rewarded with a new research grant of £1.7m from EPSRC, to allow the inventors to collaborate with Dr Zushu Li at Warwick University and Dr Rupert Myers at Imperial College, to reveal the underlying science behind the new process. The new grant will fund an additional team of researchers, to probe the range of concrete wastes that can be processed into Cambridge Electric Cement, evaluate how the process interacts with steel making, and confirm the performance of the resulting material.

Professor Allwood said ‘If Cambridge Electric Cement lives up to the promise it has shown in early laboratory trials, it could be a turning point in the journey to a safe future climate. Combining steel and cement recycling in a single process powered by renewable electricity, this could secure the supply of the basic materials of construction to support the infrastructure of a zero emissions world and to enable economic development where it is most needed.’